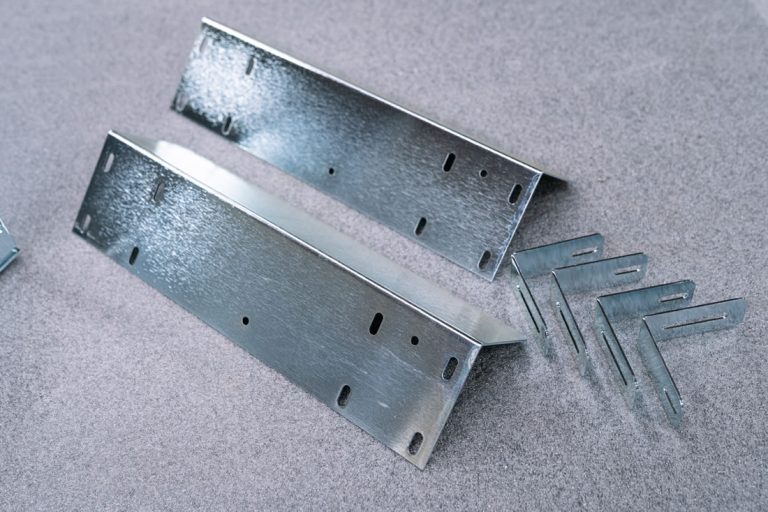

At CSE, we fabricate high-quality frameworks using a range of metals including mild steel, stainless steel, and aluminium. We use hollow sections, channels, and angles to produce custom frames that meet your specifications. Our expertise in MIG (metal inert gas) and TIG (tungsten inert gas) welding ensures strong joins, utilizing laser cut hollow sections to create frames which are fabricated on ‘machined flat’ bench tables to ensure accuracy. Large structures and frames can be easily moved using our overhead gantry crane.

Each frame is finely dressed to ensure smooth, continuous surfaces and seamless corners which continue the radius of the section. We then powder-coat the frames in-house to deliver durable finishes in your chosen colour and texture.

Current sectors supplied are robotic and automation, food packaging equipment, Scientific and medical frameworks.

Capabilities

As part of our extensive in-house workshop, CSE has the following machines:

LVD 4KW Laser cutting machine

- 1500 x 3000 rotating beds

- 20mm mild steel

- 12mm stainless steel

- 10mm Aluminium

Lissmac SMD Metal finishing

- Brush finish and barrel deburr

- 950mm wide bed

Mayer Pillar drill

HRB Amada Press Brake X 2

- 3 metre bed

- 100 Ton

- HFE tooling

- Amada off line programming

Pem inserting machine X 2

- Inserting male and female threaded bushed and studs

Avdel inserting guns X 2

Taylor Stud welding machines X 2

Tecna TE101 Spotwelder

- 62 A

MIG and TIG welding bays X 6

Over head crane X 2

Bison Powered Rollers

- 1250mm wide

Chop saw

Powder coating booth X 2

- 3 meter X 2 metre

Powder Coating oven X 2

- 3 meter X 2 metre